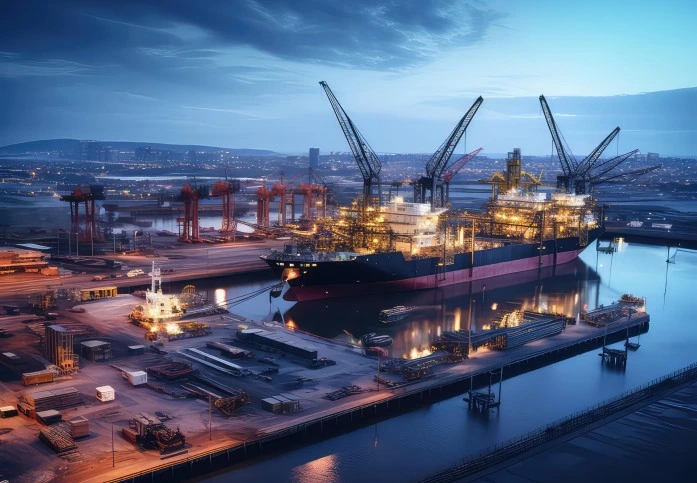

Engineering Design Services for the Oil and Gas Industry

Engineering Services

Our engineering team brings a wealth of knowledge, experience, and expertise across industries to your projects.

Process Design Package

Transform your project concepts into actionable designs with our comprehensive design development services. Regulatory compliance: guidance on meeting industry standards and regulatory requirements. Ingenero delivers process design packages (pdps), which defines the business need & establish the objective. Pdps comprise a collection of documents containing vital technology and process details. It also identifies & defines alternatives to meet the objectives. Pdps serve as essential references for the designated engineer or the engineering, procurement, and construction (epc) contractor assigned to execute a detailed design. Ingenero's pdps define the precise process operating conditions and equipment specifications needed to attain the desired levels of reliability, efficiency, and safety. +50%/ -30% tic cost estimation based on equipment costing can be done post pdp.

Basic engineering design package

It is initial stage of engineering design focusing in defining project requirement, conceptual design, feasibility studies & recommendations for optimizing designs to enhance performance and cost-efficiency. Ingenero provides basic design engineering services, encompassing core project documentation such as process flow diagrams, heat and mass balances, piping and instrumentation diagrams (p&ids), control and operational philosophies, preliminary equipment sizing, equipment specifications, and conceptual equipment layouts, instrument list, electrical load list & single line diagrams. It covers engineering of selected design options and evaluation of utilities required for selected option w.r.t. Existing utilities available at site. +25% /-15% tic cost estimation based on equipment costing and bulk material take-offs can be carried out in basic engineering.

Front end engineering design package

Feed package is a critical phase which bridges basic engineering & detail design. Overall feed aims to set a solid foundation for successful project execution and minimize unforeseen cost and delays during the later stage of project. Ingenero provides front end engineering design (feed) services, which establishes technical, project-specific requirements to ensure that the project’s scope is implicit. It develops the project’s strategy and the system’s design foundation and provides the cost estimate for the project to get budget approval. It also contributes to the risk mitigation of the project and forecasts the length and timeline of the project during the detailed design phase. Major deliverables in feed package are technical specifications, equipment layout, preliminary electrical & instrumentation cable routing layouts & substation layout. +/-15% cost estimation based on equipment costing and bulk material take-offs can be done post feed engineering.

Project Phases: Tailored Engineering Services for Success

We are experienced in a multitude of software & standards specified by clients and regulatory bodies

Concept Phase

- Process Design Package (PDP)

- Front End Engineering Design (FEED)

- Simulation & Modeling

Decision Phase

- Process Design Package (PDP)

- Front End Engineering Design (FEED)

- Simulation & Modeling

Construction Phase

- Process Design Package (PDP)

- Front End Engineering Design (FEED)

- Simulation & Modeling

Commission & Start Up

- Process Design Package (PDP)

- Front End Engineering Design (FEED)

- Simulation & Modeling

Debottlenecking Solutions for Improved Production Flow

Ingenero offers debottlenecking services to the process industry, which is a critical strategy for optimizing production and efficiency. Our expertise involves identifying and eliminating constraints or limitations that hinder the smooth flow of a production system. We address these bottlenecks through various means, such as process redesign, equipment upgrades, or workflow improvements, helping our clients enhance productivity, reduce operational costs, and increase throughput.

Ingenero’s debottlenecking solutions are pivotal in ensuring that existing facilities operate at their maximum capacity, making us a valuable partner for maintaining competitiveness and sustainability in the dynamic process industry.

Detailed Feasibility Reports (DFR)

Ingenero offers comprehensive expertise in chemical processes across various domains, from upstream to pharmaceuticals. This experience positions us as a trusted resource for developing Detailed Feasibility Reports (DFRs/FRs) and Conceptualizing processes (CDPs) when open art solutions suffice.

- Safe, cost-efficient THF solvent recovery process

- Thorough utilities estimation including Class 4 cost assessment

- Evaluation of lab data and experimental recommendations for fuel additives plants

- Conversion of batch process to continuous for 2,5 dichlorophenol production

Process Development:

Ingenero specializes in process and product development while adhering to international safety and environmental standards. We handle various chemical reactions like:

- Acylation

- Amidation

- Amination

- Condensation

- Esterification

- Friedel-Crafts

- Hydrolysis

- Hydrogenation

Our services include

- Concept testing

- Optimizing reaction conditions

- Purifying products

- Developing analytical methods

Process Scaleup

To bring laboratory technology into industrial use, scaling up is necessary from small bench-scale (0.1 to 1 liter) to large industrial-scale (10,000 to 1,000,000+ liters), which presents significant challenges and risks.

Scaling up from a pilot scale helps validate lab results, demonstrate scalability, address issues like sterility and heat transfer, integrate technology processes, and reduce commercialization risks.

Ingenero conducts pilot-scale demonstrations, offering third-party verification, scale-up assistance, design, construction, and operation services. We help our clients with flow sheet conceptualization, reactor and equipment design, cost estimation (equipment, fixed, and variable), and evaluate economic viability and minimum size requirements.

Frequently Asked Questions

Detailed engineering design in oil and gas projects involves creating comprehensive plans, specifications, and calculations for building infrastructure and equipment. It translates basic designs into actionable steps, covering everything from piping to electrical systems. This phase ensures the project’s functionality, safety, and regulatory compliance in oil & gas engineering.

Basic design engineering in the oil and gas sector involves defining the overall layout and structure of the project. It sets the foundation for the more detailed design phase, focusing on key elements like process flow, system requirements, and overall project scope. This phase is essential for effective oil & gas engineering.

Oil and gas engineering services encompass detailed and basic design engineering, package design processes, as well as process and product development. These services help companies optimize operations, from initial design to ongoing support, ensuring safety, efficiency, and regulatory compliance. Oil & gas engineering companies offer specialized expertise in these areas.

For oil and gas projects, key engineering services include detailed and basic design engineering, and specialized oil and gas engineering services for system integration. Expertise in petroleum and gas engineering covers oil field engineering to chemical engineering in the petroleum industry, ensuring smooth, efficient project execution.

Challenges in oil and gas engineering include managing complex detailed engineering design, navigating environmental regulations, and optimizing operations under fluctuating oil prices. Projects often require advanced machine learning in oil and gas to predict failures and enhance efficiency, while oil & gas engineering consultants help manage risk and ensure regulatory compliance.

AI and automation revolutionize engineering design in the oil and gas industry by improving efficiency, accuracy, and predictive capabilities. Technologies like machine learning in oil and gas enhance process and product development, reduce errors, and optimize designs. This results in lower costs, increased safety, and faster project timelines in oil and gas engineering services.