Technology is constantly evolving, and the process manufacturing industry is consistently looking to improve its facilities. It looks toward more refined and innovative real-time solutions and tools that can help change its processing landscape for the better. As the industry evolves, facilities look to invest in upgrading or installing new complex solutions and systems to their processes. One such solution that has slowly gained momentum in the last ten years has been the use of Soft Sensor technology.

The focus of this article is to understand the purpose and effectiveness of soft sensors and their growth in popularity within the process industry.

Now, how exactly are soft sensors useful?

Together with predictive models, these sensors provide estimations of various conditions that can drive decision-making, thereby aiding process operation with their day-to-day responsibilities. Software-based models that use algorithms to analyze thousands of data points and relevant factors simultaneously to provide projected parameter values that are difficult to measure directly create soft sensors. This growing trend in utilizing soft sensors is proving to be a good fit for process operators needing an alternative to traditional methods of acquiring critical data and other tasks related to process control. By employing this in tandem with their hard sensor equivalents a more comprehensive view of operations including the stability of the process, instrumentation and equipment is possible subsequently constructing a broad network for facilities to use.

The requirement to be data-driven has accelerated the development of soft sensors. These sensors are widely used in process industries such as the chemical, pharmaceutical, and bioprocessing industries that share a common characteristic — availability of large real-time data sets. Moreover, the benefit from soft sensors is high in these industries where safety and efficiency is key. Situations where the ‘speed of production’ or ‘optimized use of materials’ is a primary KPI have the incentive to work with soft sensors.

In principle, soft sensors are virtual sensors that help process available data to provide precise predictions at a much lower expense than a physical sensor. Soft sensors are the result of calculations, so there is no additional energy consumption and the capital expenditure is just for the analytics development versus paying for complex sensor hardware. Through the utilization of true sampled data the soft sensor can contribute substantial improvements through virtual data generation. This alleviates some of the concerns associated with battery-powered sensors and the need to spend large amounts of the budget on expensive hardware sensors. Additionally soft sensors can be utilized in conditions where the physical environment is not suitable for direct sampling or hardware sensors (e.g. conversion estimator at VCM furnace outlet, where the presence of HCl makes sampling impractical). This alleviates budgets restraints, increases personnel availability, and improves operating efficiency.

To give you a better idea, lets take an example. One of the common difficulties faced in the process industry is with product quality control. Accurate, constant measurement of product composition can be difficult. While, the increasing availability of precision analytical instruments helps the situation, the maintenance and often-substantial time delay linked to such instruments makes control challenging. In this case, utilizing a soft sensor provides an economical and effective solution to estimate these hard-to-measure process variables based on easy-to-measure process variables. This can help a process engineer build a multivariate data model that they can utilize to improve operational control support their decisions.

While hardware sensors are standardized and made in bulk, sensor systems are growing more complex. Unique, custom-made soft sensor technology produced by specialized companies can often simplify sensor systems making them more accurate, efficient, and easier to maintain.

Suggested Read: Soft Sensor Technology for Heat Exchangers

Here’s how Ingenero can help!

Ingenero’s I-SSPDE software offers one of the best process industry soft sensors that drives process improvement and reliability; customized to the need of operation.

Ingenero’s soft sensors ensures optimal operations by:

- Utilizing data from any given source (e.g. SQL, Excel, plant historical data, etc.)

- Providing accurate readings to address potential drifts/anomalies — analytics is driven by domain experts which ensures accuracy

- Performing real time analysis, monitoring and control to provide with predictions that can help decision-making

- Providing a stepping-stone to integrate with some of our larger solutions/tools with broader objectives like economic optimization

- Providing alerts to help operations take timely action

- Delivering sensors with forecasting capabilities, varying on the use case

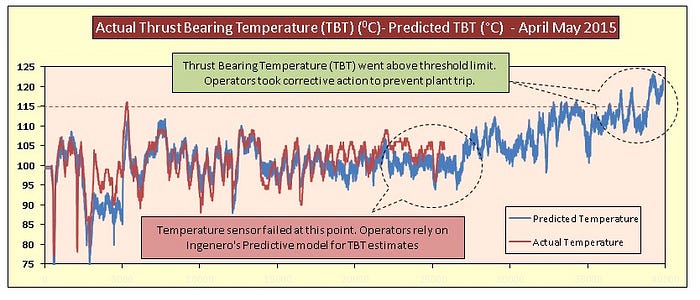

Ingenero has built and deployed soft sensors on multiple applications. Two case examples shown below:

For more information around our soft sensor technology, reach out to us at usa@ingenero.com or visit our website www.Ingenero.com.

FAQs on Soft Sensors gaining momentum in the process manufacturing industry

What is a soft sensor in process manufacturing?

It’s not a physical sensor you can hold. A soft sensor is more like a smart calculator. It uses data from your plant — stuff like flow rates, pressure, temps — and then estimates values that are hard to measure directly. It’s software doing the job, not hardware.

How do soft sensors differ from traditional hardware sensors?

Simple — hardware sensors are physical devices. You plug them in, and they give you direct readings. Soft sensors don’t do that. They work in the background, using math models and data to estimate what a real sensor might’ve read, especially for values you can’t measure easily.

Why are soft sensors gaining popularity in the chemical and pharmaceutical industries?

Because not everything can be measured directly, especially in those industries. Soft sensors give insights into things like purity, fouling, or reaction rates without needing extra devices. And let’s face it, installing more hardware isn’t always easy or cheap.

What are the key benefits of using soft sensors in manufacturing processes?

They help you keep things running smoothly. You get more visibility without more equipment. Better control, fewer surprises, and smarter use of data you already have. Plus, they save money in the long run — no added hardware, less manual testing.

Can soft sensors improve product quality control in real-time operations?

Yeah, they can. If you can “see” what’s happening inside a reactor or exchanger without waiting for lab samples, you can fix things faster. That leads to better consistency and fewer bad batches.

How do soft sensors help reduce operational costs and downtime?

Well, if you know something’s drifting before it becomes a real problem, you can fix it early. That means fewer shutdowns and less wasted material. Also, since you’re not depending only on lab tests or manual checks, you save time too.

What data sources can soft sensors integrate with in process industries?

Pretty much anything — DCS, SCADA, PLCs, lab reports, even spreadsheets if needed. As long as the data’s available and reliable, it can be used in the model.

Are soft sensors reliable for use in hazardous or hard-to-reach environments?

Definitely. That’s actually one of their main advantages. You don’t need to install hardware in tough spots. Soft sensors just use data from existing points and calculate the rest — no need to physically be there.

What are some real-world applications or case studies of soft sensors in manufacturing?

They’re used in heat exchanger fouling prediction, reactor monitoring, and catalyst tracking, just to name a few. Some plants have cut lab testing time or avoided breakdowns just by using soft sensors to catch early warning signs.

How can Ingenero’s I-SSPDE solution enhance operations with soft sensor technology?

Ingenero’s I-SSPDE is like a toolbox for setting up soft sensors across your plant. It helps you build models, connect data, and get real-time results without a full system overhaul. Teams use it to save time, improve control, and make better process decisions.